Flower Heat Pump Dryers

Product Description

Air is heated and tumbled through the goods, and then cooled with the water drained off, and then reheated again to go back through the goods. No moisture is released into the air. They are most energy efficient dryer and they do not need an external duct so can be placed anywhere. Heat pump dryers are ideal for you who want to cut down on their bills.

Industrial heat pump dryer for Tea or other agricultural product leaves, Bacon, food, fruit, chemical, cloth, save 50% to 70% energy bill

Materials of low temperature drying, keep materials no deformation, metamorphism, oxidation,during drying process.Keep long storage period, more effective than traditional drying equipment to protect items color, aroma, taste and individual form and active ingredients, close to the natural drying, by high dry matter grade, no pollution, conforms to the environmental and health requirements; The full heat recovery system can be configured, maximize reduce energy consumption; Automatic control, convenient operation, can be set different drying curve, can meet the needs of different drying, the temperature control precision, small ripple; Can use with traditional steam, electric heating, infrared, microwave drying combined, shorten the drying period, saving running costs.

Detailed Introduction

1) Heat Pump For The Dryer

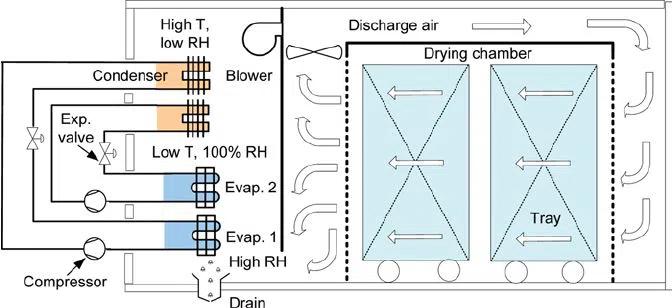

Heat pump working like air conditioner,save energy, The working principle is: the refrigerant is compressed by the compressor to become high-temperature and high-pressure gas, enters the condenser, and condenses liquefied heat, which is used to heat the drying room to provide the temperature of the drying room. The moisture in the material is vaporized and evaporated by hot air. The evaporated water vapor is patted away by the dehumidification system to achieve the purpose of dehumidifying the dried materials. The dehumidification system uses a heat recovery device. The recovered heat is used to heat the fresh air, which can save 60%. % -70% of the fresh air preheats energy consumption to achieve further energy savings.

2) Equipped with PLC touch screen system

through the manual operation system and set the working data.Using temperature and humidity sensors, we can see the internal temperature and humidity through the display screen.

It comes with a high-definition screen.its has English language to operation the dryer

3) Set drying time and drying temperature

You can set different temperatures during different working hours.

After drying, the dryer will automatically stop.We just need to push the finished product into the dryer with trays and trolleys, and then push it out after it is finished. There is no need to operate during the drying period.

4) Fan

Depending on the size and volume of the dryer, there are 8 or 16 sets of fans in the dryer.And the fan resistant to high temperature corrosion.These fans are designed to provide a heating cycle that ensures even circulation of temperature within the dryer so that all materials are well dried.

Product Application

Application Scope Of Heat Pump Dryer:

Because the heat pump dryer is not affected by the external environment, weather, season and climate, it can work continuously for 24 hours, and can well guarantee the quality, color, appearance and effective composition of the dried products, It can meet the drying requirements of different products, so it can be widely used in the drying of agricultural and sideline products, aquatic products, meat products, traditional Chinese medicine, fruits and vegetables, food, grain, seeds, clothing, tea, paper and other fields.